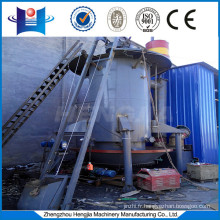

High quality coal gasifier used to produce coal gas hot selling in Pakistan and South America

Informations de base

Modèle: HMCQ

Description du produit

High quality coal gasifier used to produce coal gas hot selling in Pakistan and South America

HJ coal gas gasifier/coal gasifier is the process of producing coal gas, a type of syngas–a mixture of carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2) and water vapour (H2O)–from coal and water. Coal gas, which is a combustible gas, was traditionally used as a source of energy for municipal lighting and heat before the advent of industrial-scale production of natural gas, while the hydrogen obtained from gasification can be used for various purposes such as making ammonia, powering a hydrogen economy, or upgrading fossil fuels. Alternatively, the coal gas (also known as "town gas") can be converted into transportation fuels such as gasoline and diesel through additional treatment via the Fischer-Tropsch process.

The coal gas gasifiers we manufacture use steam and air as the agent for the mixed coal gas production. The process is that air from blower and self-produced 0.294Mpa steam is mixed to be saturated air as the gasifying agent and comes into gasifier from its bottom via the check value. The block coal is broken up and filtrated to size of 25~50mm or 50~100mm. Then the coal is fed into the coal gasifier by coal feeding system. The gas produced in the stove finally transported to end users after dust removed by gravitational dust cleaner and cyclone dust cleaner.

1. Mechanical industry: high manganese steel hardening furnace, annealing furnace, aging furnace, mold shell baking furnace, forging furnace…

2. Metal industry: aluminum melting furnace, melting copper stove, magnesium smelting furnace…

3. Building material industry: building ceramics, sanitary ceramics, glass, porcelain, grinding wheel refractories…

4. Chemical industry: chemical products drying and calcinations…

5. Non-metallic industry: mineral aggregate drying and calcinations…

6. Boiler: variety of hot water boilers, steam boiler furnace…

7. Other industries: food dehydration and drying, vegetable and flowers greenhouses heat supply…

1. HJ coal gas furnace with 1.5kg standard coal = 12 kw/h electricity =1.1kg diesel

2. Reduce more than 70% cost comparing with electrical furnace, cost 60% lower than oil furnace, reduce 30% cost more than coal stove.

3. Automatic power control system, precise temperature control and high quality heating supply.

4. Continuous automatically deslagging, stable gas producing, convenient operation.

5. Environment friendly and comply with the emission standards of GB9078-96.

Advanced technical design for auxiliary parts on HJ brand coal gas gasifier:

1. Adopting the bucket elevator coal adding system and double bell coal feeding mechanism, the sealing effect is better than before. Combined the adjustable pocket flap and conical coal distributor, the coal can be scattered uniformly, so as to improve coal gasification efficiency, avoiding the un-normal flaming phenomenon.

2. Adopting full water jacket, the steam self-production rate has been improved. No need to provide steam from outside, and the pressure will be stable, it’s better for gasification effect.

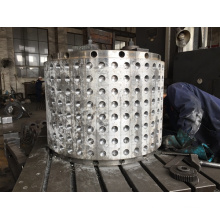

3. Adopting tower type pyramid pentagonal grate on the wet rotary ash plate and the material is made by the steels casting, also design a small ash knife to push slag and mechanism to break and press coal slag, it can make the gasification catalyst distributed and the slag falling out uniformly. All the modified structure can make the gasifier has best gas production rate.

4. Adopting isolation of water dust catcher, when the outage of electric and the whole machine, it can improve the sealing effect of the water, so as to cut off the coal gas between gasifier and furnace, guarantying there’ no pressure in the gas pipes and avoiding the tempering explosion.

5. Use the refractory concrete as the roof insulation, it can save cooling water. The coal gas burner is specialized by different models and using conditions, which has features like burning fully, stably operating and service life extended.

Before sales service:

Provide the program design and technological flow design; choose the right equipment that most suitable for you. Design and manufacture products according to your demands, provide training of operational technicians.

Sales service:

Finish the equipment inspection for you, assist you in drawing out the construction scheme and detailed flow.

After sales service:

Send technicians to installation site for the guidance, equipment adjustment and training.

We have established favorable service theory: repair in time broken-down equipment; provide program design and technological flow design to customers before sale; provide high quality products and operation training and tentatively help customers to solve complicated processing problems.

Our telephone services are available around the clock including holidays.

Located in Zhengzhou, the construction machinery town of China, Zhengzhou Hengjia Machinery Manufacturing Co., Ltd was established with the goal to become one of the leading manufacturers in the machinery industry in China.

As one manufacturer, we have over 10 years of experience in manufacturing, designing, testing and R&D. Our main products include dryer equipment, coal gas gasifier, heating stove, and spare parts of equipments etc. Welcome customers at home and abroad to choose!

Groupes de Produits : Équipement de gazogène > Gazéificateur de charbon

Premium Related Products