2014 hot selling electric grain dryer

Informations de base

Modèle: HJ series

Description du produit

Specifications

electric grain dryer1. Capacity:30-1000t

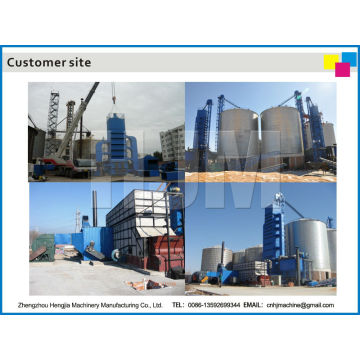

2.Global Drying Tower sales & service

3.Low Energy Consumption

4.Passed ISO9001

2014 hot selling electric grain dryer

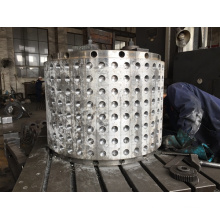

HJ Tower grain dryer is mainly composed of drying section, cooling section, discharging section, etc. It adopts mixed flow drying technology and can conduct one-time or circulated drying with the medium of clean hot air. Grain flows slowly from top to bottom along the channel between angular boxes under the influence of gravity, while the hot air comes into the dryer through the angular box, and then passes through the grain layer, flows to the surrounding air exhaust boxes, turns into exhaust gas, and eventually gets discharged from the air exhaust box. The heating up temperature of grain in the dryer is an alternating process. Thin grain layer, low fan power and low power consumption result in lower cost. The hot-blast stove is composed of the furnace body, the heat exchanger and other components. It takes coal, straw, waste wood, rice husk as its fuel. The heat exchanger is made of heat resistant material, so it has high thermal efficiency and long service life.

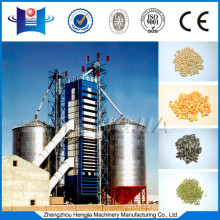

HJ brand tower type grain dryer is suitable for drying high moist paddy, wheat, mung bean, sorghum, rape seed, and other grains. It is mainly used among small and medium size grain supply center, farms, self-planting grain farmers, etc.

Even drying, quality of dried grain can be maintained. Grains are free from pollution through indirect heating, clean air is heated through a heat exchanger by hot air generated from burning of coal and stalks.

Tower dryer is also called the grain dryers, grain drying machine is an ideal equipment for drying grain and oil, processed products from the top input, through the feeding device, to ensure that the equipment always in full load condition during operation. After turning inward bottomless v-shaped flap and processing with staggered joint action of multiple rows of "V" baffle, makes possible the mix of processed products, but also as dry air in and out of the channel, the fan will be used gas into the collector, purification, most of the dry air can be recycled, so save the fuel consumption.

1. Outdoor dryer can reduce building cost

The outdoor dryer needn’t build a drying room, small area occupation, shorten the installation period, reduce the cost of the whole equipment; they are very helpful to achieve profitable operations.

2. High moisture paddy or wheat can be dried easily

The internal distribution of “v” shape “hill-shaped multi-tube structure” can circulate mixing grain perfectly, prevent drying inhomogeneous, crackle, over drying etc, high moisture paddy or wheat can be dried easily and the quality can be guaranteed after drying by low temperatures, high winds, comprehensive ventilation structure.

3. Installation working hours can be reduced by semi-products delivery

Many parts have been assembled before delivery, it can reduce installation working hours, reduce the time limit from project and costs on site. In addition, wires and pipe work, wiring material, and the air pipe etc are also carried out simultaneously, when the completion installation of the mechanical parts, they can also be finished together at the same time.

Model |

HJ100 |

HJ150 |

HJ200 |

HJ300 |

HJ400 |

HJ500 |

HJ600 |

|

Handling Capacity (Ton/Day) |

100 |

150 |

200 |

300 |

400 |

500 |

600 |

|

Decreased Moisture (%) |

2~16 |

|||||||

Heated method |

Fresh air |

|||||||

Hot blast Temperature |

65°C~120°C |

|||||||

Unevenness of drying (%) |

< 2 |

|||||||

Crush Ratio |

< 0.3 % |

|||||||

Heat Consumption |

5450~6700 (KJ/kg H2O) |

|||||||

|

Coal Consumption (kg/h) (standard coal) |

60-230 |

90-345 |

120-460 |

150-575 |

180-690 |

240-1000 |

300-1380 |

|

Power |

According to environment, condition, decreased moisture and configuration |

|||||||

Size of Main Machine(M) |

4*3 |

4*3 |

5*3.2 |

5.5*3.2 |

5.5*4 |

5.5*4.5 |

6*6 |

|

Length of Main Machine(M) |

6~12 |

8~15 |

13~17.5 |

14~18 |

14~19 |

15~20 |

16~22 |

|

Material |

Wheat, paddy, corn, soy, rice, seed, etc. |

|||||||

Remarks |

Except the above general types, we can also supply special models as your request. |

|||||||

1. How is the quality of HJ series grain dryer machine? Will the material be burnt or dried? Can it be dried evenly?

A: After drying, the grain can reach the National Standard of Grain Seeds and it can be used for starch, edible grain and feed grain. The grain, after drying by the downstream and counter-current grain dryer, has no difference with the sun dried food and has even moisture without burnt or dried particles. About this, you can investigate among our clients during the drying period.

2. What is the drying cost? Is the machine energy-saving? Can all the coals be the fuel?

A: The most important feature of our grain dryer is energy-saving, which can minimize the cost and maximize the profit. For example, the 100-ton grain tower can help you earn 20 thousand dollars more than others in one drying period. Also, only if it can be burnt, it can be the fuel.

3. What kind of grain dryers do you have?

A: We have more than 20 models of grain dryer. In terms of the structures of the tower, they can be divided into cross-flow, mixed-flow, downstream and counter-current tower. In terms of the hot-air furnaces, they can be divided into mixed-wind and recuperative furnace. In terms of the working forms, they can be divided into continuous and intermittent circulating dryer. You are also welcomed to our factory.

4. How is your after-sale service?

A: We declare that after-sale service is an important step during our sales. We have set up good service philosophy: to provide considerate customer training, timely and effectively to repair the malfunction of the equipment and solve the difficult processing problems for the customers.

We accept EXW, FOB, CIF, etc. payment terms. Some cargos are packaged in containers in our factory, some are sending to the port and then delivered. Our products also sell well abroad.

Any questions please contact me freely. We also appreciate your coming for visit!

Groupes de Produits : Matériel de séchage > Séchoir tour