Energy-saving hot blast stove work with diesel burners

Informations de base

Modèle: HLF

Description du produit

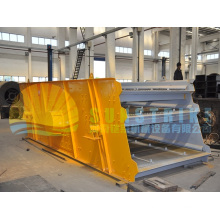

Energy-saving hot blast stove work with diesel burners

Summary of hot blast stove:

The series of HLF type vertical hot-blast stove are high-efficience and energy-saving products developed by our corporation. Matched with special drying device, this hot-blast stove applies to dewatering of grain, food, fodder, fruits and vegetables and other industries which need hot-blast.

Structural principle of hot blast stove:

The hot air furnace collect combustion and heat transfer as a whole. Either smoke or air has its own way. The hearth itself has heat transfer effect. Smoke flue and air flue are crossed and strictly insulated. Under the effect of draft fan, smoke and cold air rotate and flow reversely, and become pure hot blast through heat sink. Then the hot blast is sent to the dryer by hot air blower.

Characteristics of hot blast stove:

1.Use ordinary industrial coal, firewood and rice husk as its fuel, air as the heat-transfer medium. It has high efficiency and is energy saving, safe and reliable.

2.The hot-blast stove itself has dedusting function, so another dedusting equipment is saved, which meets the environmental protection requirement.

3.The temperature range of outlet hot blast is large; the warming speed is rapid; the blast capacity is adjustable; it is easy to install and meets different technology requirements.

4.Good heat-transfer effect and high heat energy use ratio.

5.Smoke flue and hot-blast flue are strictly insulated from each other, so hot-blast drying won’t pollute the material.

Parameters of hot blast stove:

Specification |

Heat Supply (kcal/h) |

Thermal Efficiency (%) |

Hot Air Temperature |

Coal Consumption (standard coal) |

Weight reference(t) |

HLRF5 |

5*104 |

≥70 |

60-230°C |

15-20 kg/h |

* |

HLRF10 |

10*104 |

≥70 |

60-230°C |

25-30 kg/h |

1.3 |

HLRF20 |

20*104 |

≥70 |

60-230°C |

45-55 kg/h |

1.6 |

HLRF30 |

30*104 |

≥70 |

60-230°C |

70-85 kg/h |

2.3 |

HLRF40 |

40*104 |

≥70 |

60-230°C |

100-120 kg/h |

3.8 |

HLRF60 |

60*104 |

≥75 |

60-300°C |

150-170 kg/h |

4.2 |

HLRF80 |

80*104 |

≥75 |

60-300°C |

200-220 kg/h |

9.0 |

HLRF100 |

100*104 |

≥75 |

60-300°C |

250-275 kg/h |

12.8 |

HLRF120 |

120*104 |

≥75 |

60-300°C |

310-330 kg/h |

14.2 |

Remarks |

Besides the above models, we can also supply special models as your request |

||||

Certification:

About Zhengzhou Hengjia Machinery

Zhengzhou Hengjia Machinery Manufacturing Co. , Ltd. is a joint-equity enterprise, which is specialized in research and development, producing and manufacturing of all kinds of drying machinery and energy conservation and environmental protection heat source.

The dryer developed by our corporation for the drying of coal slime, sludge, saw dust, sand, coal ash, flue gas desulfurization gypsum, sprayed corn bran and all kinds of food and mining industry has professional technical ability and distinguished product performance and sell very well in more than 30 provinces of China, also in abroad, like Russia, Korea, Vietnam, India, Malaysia, Indonesia, Pakistan and so on.

Any questions please contact us freely. We also appreciate your coming for visiting our wood dryer!

Skype: lisa.hjm

Groupes de Produits : Chauffage poêle équipement > Bois et charbon poele

Premium Related Products